Detalji o proizvodu

Certifikacija: ISO9001: 2008

Uvjeti plaćanja i slanja:

Minimalna količina porudžbine: 1

Cijena: NEGOTIACIJA

Detalji ambalaže: DRVENI SLUČAJ

Vrijeme isporuke: 15 DANA

Sposobnost snabdijevanja: 2000 jedinica

Detaljan opis proizvoda

| Ime: | Mašina za lasersko rezanje metalnih vlakana | Primjena: | Medical Equipment |

|---|---|---|---|

| Značajka: | Medium - Power | Ostalo ime: | Cnc Steel Cutting Machine |

| Tip lasera: | Fiber laser | Certifikat: | ISO9001: 2008 |

Features of metal laser cutting machines

* The medium-power laser cutting machine with the highest precision in China, it can cut small metal bike design with size of half a coin and good cut 6mm mild steel,120 holes can be cut within one minute.

* 600℃ heat treatment, 24 hours cooling in the oven, 8 meters gantry milling, accurate CO2 protection welding, to make sure 20 years usage without deformation.

* Using laser electrical cabinet integration design, cover small area , save space, minimalist design.

* Scrap car symmetrical design, both sides can clean up the waste; Put machine to the romm has no left and right requirements; Pneumatic lifter device to prevent the material from scratching.

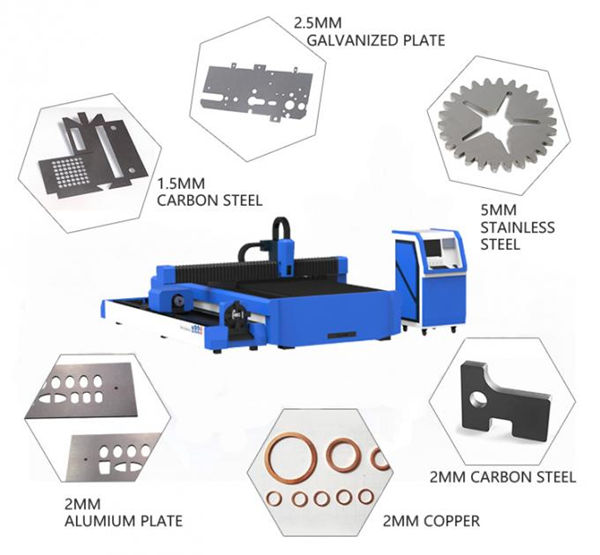

* Specially used for cutting 0.5-6mm carbon steel, 0.5-5mm stainless steel, galvanized steel, electrolytic zinc-coated steel sheet, silicon steel and other kinds of thin metal sheets.1000W can cut 3mm aluminum and 2mm copper.

Machine characters

* Using gantry type mechanic structure , performance is stable .

* Aheadcut USA fiber laser control system, with laser power adjusting function ,

* This model adopts servo motor driving system.machine bed movement structure using high accuracy gear to transit , so to ensure the high speed , high precision and high reliability.

* Using Raytools Switzerland fiber laser cutting head,safe and stable.

* Adopts Maxphotonics fiber laser source ,which is with imported modular high performance, low processing cost ,Eco-friendly .

Tehnički parametar

| Predmet | Parametar |

| Laserski tip | Vlaknasti laser |

| Talasna dužina | 1070-1080nm |

| Učinkovitost elektro-optičke pretvorbe | 25-30% |

| Ruta XYZ | 3025mm / 1525mm / 100mm |

| Materijal Debljina rezanja | 0.2-8mm |

| Širina šava za rezanje | 0.1-0.2mm |

| Ponovite tačnost položaja | ± 0,05 mm / 500 mm |

| Tačnost pozicioniranja | ± 0,05 mm / 500 mm |

| Maks. Brzina kretanja | 60000mm / min |

| Maksimalna brzina nogometa | 0,8g |

| Maks. Težina opterećenja | 500kg |

| Težina mašine | 2300kg |

| Potrebna snaga | 220V 50Hz / 60Hz |

| Veličina mašine (D * Š * V) | 4500mm * 2450mm * 1700mm |

Primenjena polja mašine za lasersko rezanje

mašina za rezanje laserski Metal je naširoko koristi u hardver, precizan mašina, automobilskih komponenti, čaše satovi i satovi, precizno rezanje, medicinske opreme, instrumenata i drugih srodnih industrija metala.

Može se obrađivati bezkontaktnim rezanjem lima, cevi, posebno za nehrđajući čelik, sttel ploču, diomondne pile i druge metalne materijale, a ima i odličan proces za razne visoke krhke legure. U liniji industrije hardvera i metala, tehnologija laserskog rezanja može djelomično zamijeniti rezanje linija.